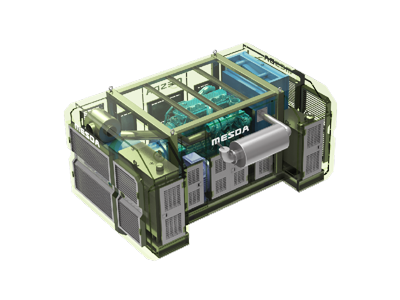

Sieve the particle size of the final project accurately.

Generator included

Powerful screening ability

Complete spare parts and screener support

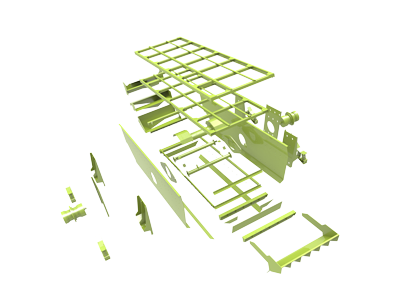

| PROJECT | NAME | PT-7020C | COMMENT |

| Hopper | Feeding capacity(t/h) | 350 | |

| Max feed size(mm) | 200 | ||

| Feeding height (mm) | 2600 | ||

| Length x Width(mm) | 10500 × B1000 | ||

| Power (kw) | 15 | ||

| Volume (m³) | 3 | ||

| Vibrating screen | Length × width(mm) | 7000 × 2000 | |

| Power (KW) | 28 | ||

| Desk | 3 | ||

| A conveyor(1st desk) | Discharge height (mm) | 3550 | |

| Length x Width(mm) | 7170 × 650 | ||

| Power (KW) | 5.5 | ||

| B conveyor(2nd desk) | Discharge height (mm) | 3550 | |

| Length x Width(mm) | 7175 x 650 | ||

| Power (KW) | 5.5 | ||

| C conveyor(3rd desk) | Discharge height (mm) | 3550 | |

| Length x Width(mm) | 7175 x 650 | ||

| Power (KW) | 5.5 | ||

| D conveyor(bottom desk) | Discharge height (mm) | 3850 | |

| Length x Width(mm) | 7590 x 1000 | ||

| Power (KW) | 7.5 | ||

| Whole machine | Engine Power (KW) | 125 | |

| Generator power (kw) | 100 | ||

| Total power (KW) | 67 | ||

| Total weight (t) | 37 | ||

| Output capacity(t/h) | 150-350 | ||

| Transport dimension(L x W x H/mm) | 15300 × 36000 × 38000 |

Description:

1. The parameter in brackets is the onboard generator scheme.

2. Crusher processing capacity is related to stone hardness, feed size, and discharge size.

3. Basic configuration:manual control 、wireless remote control、Automatic feeding system.

4. Options:side conveyor belt 、iron remover 、water spraying system.