Can crush almost any material.

Can operate stably for a long time

Capable of handling various harsh working conditions

Easy maintenance and cheap

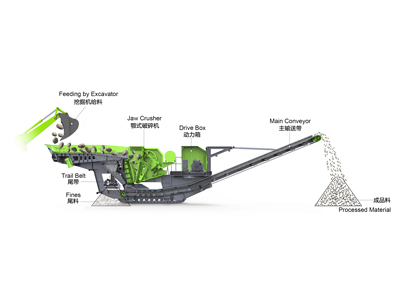

| PROJECT | NAME | MC-116J | COMMENT |

| Feeder | Feeding capacity(t/h) | 450 | |

| Input size max(mm) | 700 | ||

| Feed height (mm) | 4100 | ||

| Hopper volume (m³) | 5 | ||

| Vibrating feeder | Length × width(mm) | 4000×1040 | |

| Power (KW) | 3.7 × 2 | ||

| Jaw crusher | Jaw crusher | J-116 | |

| Crusher opening size(mm) | 1060 × 750 | ||

| Input size max(mm) | 700 | ||

| Weight(t) | 20 | ||

| Power(KW) | 110-6 | ||

| Main conveyor | Discharge height(mm) | 3200 | |

| Length × width(mm) | 13000×B1200 | ||

| Power(KW) | 15 | ||

| Extend conveyor | Discharge Height (mm) | 2100 | |

| Length × Width(mm) | 3600×B500 | ||

| Power(KW) | 3 | ||

| Iron remover (options) | Length × Width(mm) | 1670 × B800 | |

| Power(KW) | 3 | ||

| Whole machine | Engine power(KW) YuChai | 70 | |

| Total weight (t) | 45 | ||

| Crushing capability(t/h) | 130-480 | ||

| Total power of crushing operation(KW) | 135(138) | The iron remover is included in the brackets | |

| Transportation dimensions(L × W × H/m) | 16.24 × 3.35 × 3.78 |

Description:

1. The parameter in brackets is the onboard generator scheme.

2. Crusher processing capacity is related to stone hardness, feed size, and discharge size.

3. Basic configuration:manual control 、wireless remote control、Automatic feeding system.

4. Options:side conveyor belt 、iron remover 、water spraying system.